![]() Direction of air flow:Follow the arrow direction on housing, from inside to outside of filter, for installation.

Direction of air flow:Follow the arrow direction on housing, from inside to outside of filter, for installation.

![]() Manual drain eliminates water regularly, and steamed by-pass valve is disposition for selection.

Manual drain eliminates water regularly, and steamed by-pass valve is disposition for selection.

![]() Compressed air should be liquid, impurities and oil-free beforeg injecting into the housing, and 3-stages qualified pre-filtration is required for sterile filter.

Compressed air should be liquid, impurities and oil-free beforeg injecting into the housing, and 3-stages qualified pre-filtration is required for sterile filter.

![]() Do sterilization regularly:1~2 times a week, 20~30mins each time. Utilizing sterile filter,which is under critical proccess of clean steam

with 1 micron rating, ex. steam temperature < 130℃ ,pressure < 2.5bar. If steamed pressure is higher than designed one,and then pressure reduced valve should be distributed.

Do sterilization regularly:1~2 times a week, 20~30mins each time. Utilizing sterile filter,which is under critical proccess of clean steam

with 1 micron rating, ex. steam temperature < 130℃ ,pressure < 2.5bar. If steamed pressure is higher than designed one,and then pressure reduced valve should be distributed.

![]() Used sterile filter must be drying by clean compressed air, and increases pressure by opening valve steadily before reuse.

Used sterile filter must be drying by clean compressed air, and increases pressure by opening valve steadily before reuse.

![]() Filter replacement should be done when pressure drop reaches 0.7~1 bar or 50 times steam sterilization.

Filter replacement should be done when pressure drop reaches 0.7~1 bar or 50 times steam sterilization.

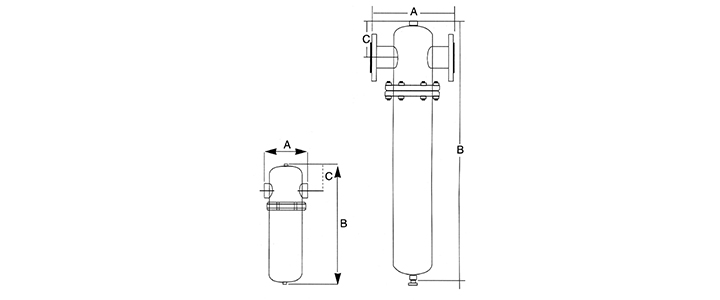

| Specifications | ||||||

|---|---|---|---|---|---|---|

| Type | Flow Rate m3/Min |

Inlet/Outlet | Dimensions(mm) | Element Model | ||

| A | B | C | ||||

| AZ-15G-1 | 1 | DN15 | 180 | 340 | 80 | EAZ-1 |

| AZ-20G-2 | 2 | DN20 | 180 | 340 | 80 | EAZ-2 |

| AZ-25G-3 | 3 | DN25 | 180 | 340 | 80 | EAZ-3 |

| AZ-40F-6 | 6 | DN40 | 240 | 570 | 100 | EAZ-6 |

| AZ-40F-9 | 9 | DN40 | 240 | 570 | 100 | EAZ-9 |

| AZ-50F-12 | 12 | DN50 | 240 | 820 | 100 | EAZ-12 |

| AZ-50F-15 | 15 | DN50 | 240 | 1080 | 100 | EAZ-15 |

| AZ-50F-18 | 18 | DN50 | 240 | 1080 | 100 | EAZ-18 |

| AZ-80F-24 | 24 | DN80 | 420 | 920 | 150 | EAZ-12x2 |

| AZ-80F-30 | 30 | DN80 | 420 | 1080 | 150 | EAZ-15x2 |

| AZ-100F-45 | 45 | DN100 | 420 | 1080 | 150 | EAZ-15x3 |

| AZ-100F-54 | 54 | DN100 | 420 | 1200 | 150 | EAZ-18x3 |

| Lowest Inlet Pressure(bar) | 1 | 3 | 5 | 7 | 9 |

|---|---|---|---|---|---|

| Correctional Parameter | 0.3 | 0.5 | 0.8 | 1 | 1.2 |

According to proper principle of enlargement, Filter Type AZ-40F-9 is applicable.